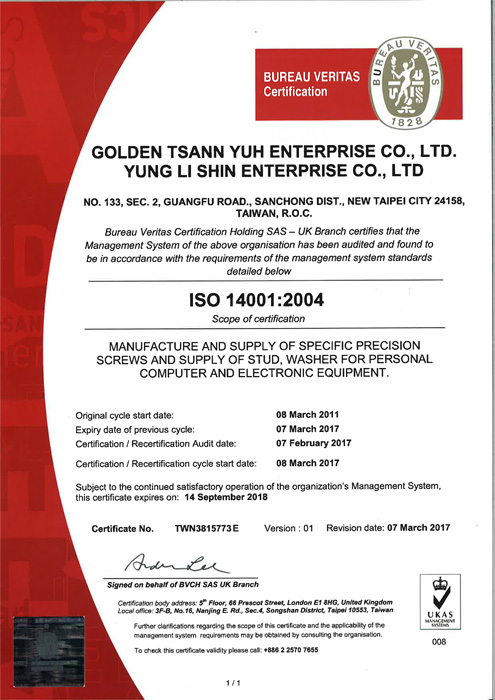

Authentication Certificate

Quality Assurance Equipment

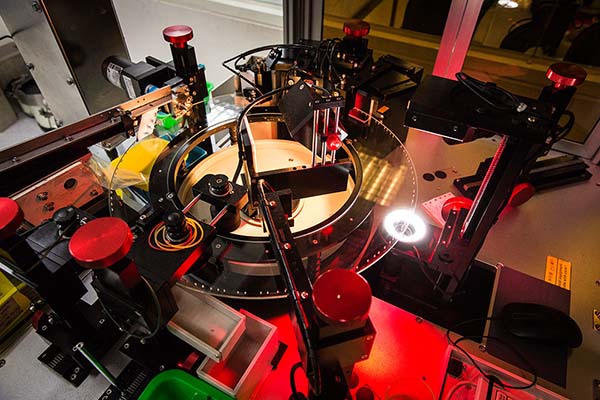

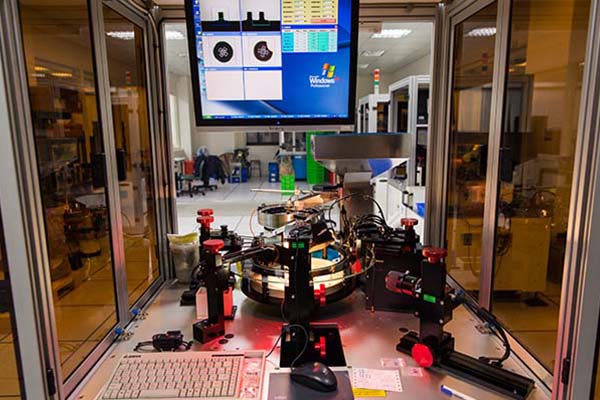

CCD Optical Sorting Machine

Function: Use the CCD camera able to directly determine if the screw product has defect or not and display the screw-related image directly, detect the unqualified screw through the image, send the signal to the mechanical rejection device to reject the unqualified product from the turntable, in the meantime, record the screw numbers of shift and numbers of unqualified screws, in order to improve the production efficiency and inspection accuracy, reduce the customer complaints.

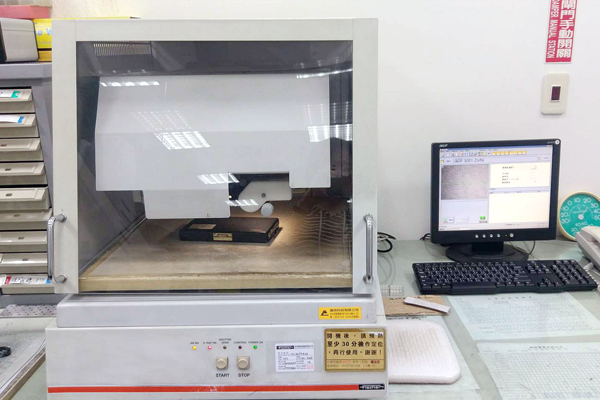

MICRO VU Image Measuring Instrument

Function: Full automatic image measuring instrument, applicable for the industries of aerospace, military, connectors, electronics and O-ring etc., it is able to combine with the probe system and laser system to construct the complex sensor measurement system, in order to complete the measurement of special sizes.

Other Inspection Equipment Includes

- Rockwell Hardness Tester

- Surface Roughness Tester

- 0.10~12.0 Plug Gauge

- 0.10~12.0 Ring Gauge

- Rockwell Hardness Tester

- Bore Gauge

- Electronic Gauge

- Various Types of Precision Small Measuring Tools (Mircometer Caliper, Vernier Scale)

- Universal Punch Corp. Concentricity Gage

- Spring torsion tester

- Screw torsion testers

- 2.5D Coordinate Measuring Machine